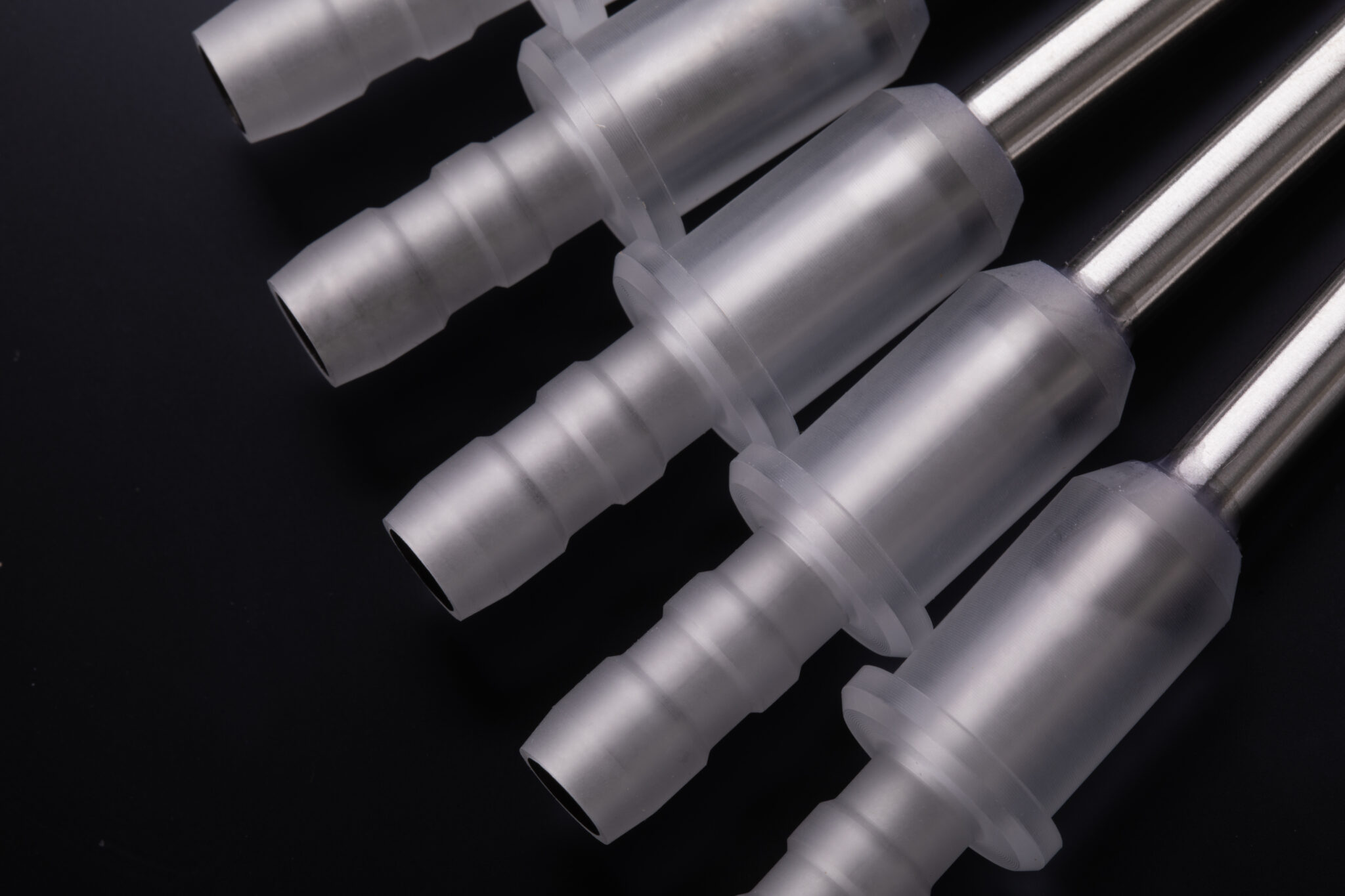

OneShot™ Single-Use Filler Needles

BOOST PRODUCTION AND ELIMINATE THE NEED FOR COSTLY CLEANING AND VALIDATION.

QUALITY IN EVERY DETAIL

ONESHOT™ FEATURES

OEM Replacements For All Fill-Finish Brands

We offer up to 20 standard sizes for the world’s most popular fill-finish machinery.

Validated Shelf Life

Hold onto inventory to utilize when needed with a validated 60-month shelf life.

Eliminate Cross Contamination

Utilize new components for each batch.

Needle Brands

ELIMINATE CLEANING & VALIDATION

WHY SINGLE-USE?

We believe that the future of liquid packaging lies in the flexibility and efficiency of single-use technology, improving operations in the following ways:

INCREASE PRODUCTIVITY

Single-use technology can significantly increase productivity by eliminating complex and time consuming steps like cleaning and validation. Pre-sterilized single-use components no longer add to the bottleneck at the autoclave and can be passed directly into the filling suite to be utilized.

Additionally, the simple disposal of single-use components immediately after their utilization significantly improves line process and changeover times.

INCREASE FLEXIBILITY

Durable components must be cleaned and sterilized prior to usage. In the event there is a last minute change of schedule, you may be left in a situation where you do not have the right components ready for a fill.

Single-use components are multi-bagged and can be provided gamma-sterilized, ready to use. All that is needed to address a changeover is to swap components from material control. Eliminate lost revenue due to scheduling issues.

LOWER PRODUCTION COSTS

Realize direct savings related to material and labor costs. Costs for water, chemicals and cleaning validation are significantly reduced. Additionally, less demand is placed on water systems, leading to prolonged operating life and further reduction in total cost of operations.

LOWER INVENTORY AND MAINTENANCE COSTS

The storage of reusable pumps and needles takes up valuable space that can be dedicated to production.

Single-use components can be purchased on a schedule that matches their usage, significantly reducing inventory-related tax burden.

LOWER ENERGY AND WATER CONSUMPTION

Biopharmaceutical production facilities utilizing single-use technologies reduce costs related to the processing and disposal of chemical-laden rinsate created during the cleaning and sterilization process.

Not only is there a strong financial incentive to do this, but also an environmental imperative to reduce the carbon footprint of production plants.

QUALITY IN EVERY STEP

MANUFACTURING & PACKAGING

Clean Room Inspection and Bagging

All needles are cleaned, assembled, inspected and packaged in an ISO 7 clean room, utilizing 4mil thick clean room quality bags.

Full Quality Inspection

Quality reviews each order prior to batch release.

Detailed Product Label

Including part-number, job number, date of manufacture and expiry or use-by date.

THE PROCESS

HOW TO ORDER

1. REQUEST A QUOTE

Please use the form below to request a quote.

2. QUOTE PROVIDED

A quote for your item will be provided, either with the requested quantity or standard price breaks.

3. SUBMIT A PO

We ask that all orders submitted to our sales team include part-number, item quantity and per-item price.

4. ORDER ACKNOWLEDGED

After receipt of PO, an acknowledgement will be sent by our sales team within 48 hours to verify order info, including expected ship date.

5. PRODUCTION BEGINS

Once your PO has been acknowledged, our production team will begin working on your order.

6. ORDER COMPLETED

Once your items are completed, they will be inspected, bagged and shipped per our QMS. Certificate of compliance accompanies each order.

QUALITY IN EVERY ORDER

EACH BATCH RELEASE INCLUDES

Overlook C of C

The full manufacturing package, including production logs and raw material certs, is maintained by quality for 5 years.

Gamma Certs and Indicators

Gamma-sterilized items include certs of process and color-changing gamma indicators on all labels.

Multi-Bagged Items

All non-sterile items are double-bagged and gamma-sterilized items are triple-bagged in clean room quality bags.

Detailed Packing Slip

A detailed packing slip provides all relevant order info to be easily handled by your receiving department.

Shelf Life

Gamma-sterilized items are validated to a 30-month shelf life from the date of manufacture.

Electronic Job Records

All job records are scanned to multiple secure locations and are available for reference upon request.