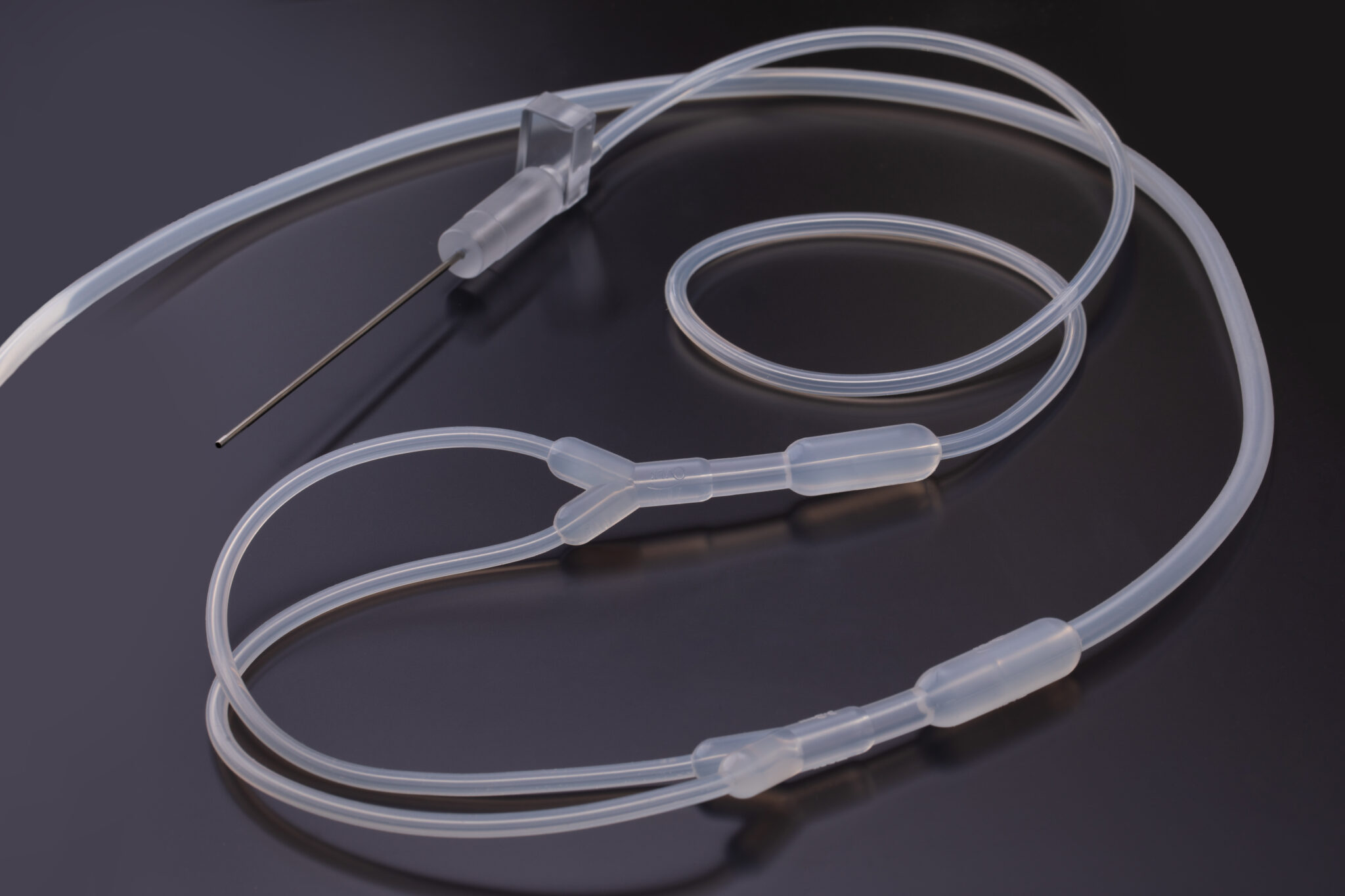

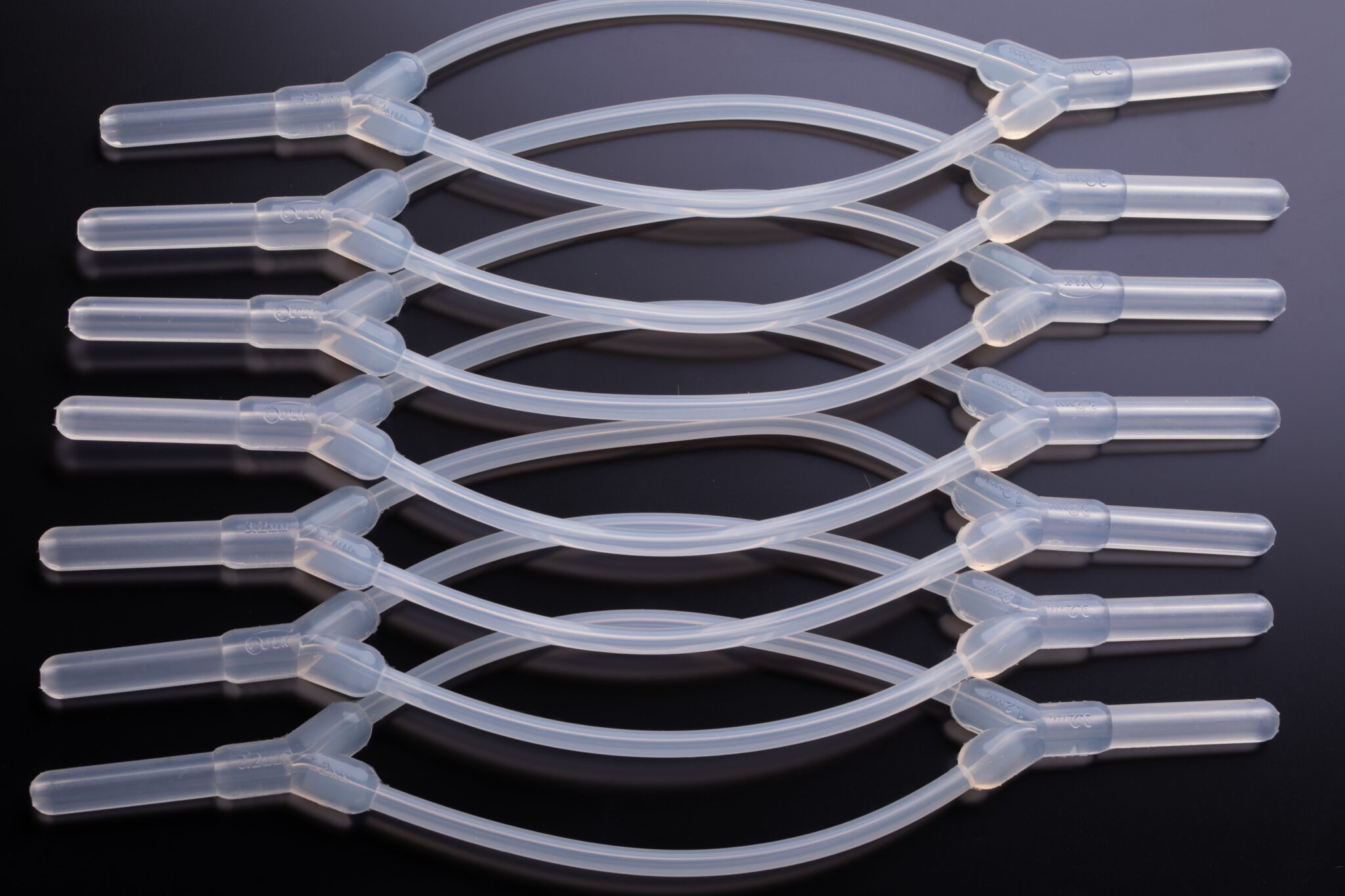

Peristaltic Pump Legs & Double-Y Pump Elements

Custom peristaltic legs and double-y pump elements for your unique product and application.

QUALITY IN EVERY DETAIL

Peristaltic Pump Leg Features

Customized For Your Product and Pump Type

Peristaltic pump legs and double-y pump elements are custom-designed for your unique application, featuring a wide variety of components and connectors to meet your requirements.

over-molded Components Available For Ultra-Precise Fills

Overlook can mold down to 0.5mm ID silicone tubing, eliminating leakage associated with cable-tied, barbed connection points.

Wide Range of Tubing Brands and Sizes Available

We work with several popular brands of platinum-cured silicone tubing, and FEP.

ELIMINATE CLEANING & VALIDATION

WHY SINGLE-USE?

We believe that the future of liquid packaging lies in the flexibility and efficiency of single-use technology, improving operations in the following ways:

ISO 7 CERTIFIED CLEAN ROOMS

Overlook products are over-molded, assembled, flow tested, integrity tested and packaged in ISO 7 clean rooms.

ASSEMBLY TECHS ARE SUITED TO ISO 5

Clean room assembly techs are suited in full body garments that exceed ISO 7 requirements to ensure maximum cleanliness.

WORLD'S SMALLEST ID over-molded COMPONENTS

Overlook has the ability to mold 0.5mm ID silicone tubing into single-piece fluid paths, eliminating restriction and the high potential for leakage associated with small ID plastic fittings.

WORLD-CLASS QUALITY MANAGEMENT SYSTEM

We are an ISO 9001:2015 certified company. Our QMS exceeds the requirements of the world's greatest pharmaceutical companies in relation to GDP, personnel training, clean room gowning and operation, and incoming materials handling and storage.

Overlook is audit-ready at all times and we welcome any questions about our SOPs and quality protocols.

QUALITY IN EVERY STEP

Manufacturing & Packaging

Clean Room Inspection and Bagging

All pump legs are assembled and packaged in an ISO 7 clean room. Bags are 4mil thick and manufactured in an ISO 5 environment.

Full Quality Inspection

All raw materials certs, routing sheets and inspection logs are reviewed by quality prior to batch release.

Detailed Product Label

Including part-number, job number, date of manufacture and expiry or use-by date.

THE PROCESS

HOW TO ORDER

1. REQUEST A QUOTE

Please use the form below to request a quote.

2. QUOTE PROVIDED

A quote for your item will be provided, either with the requested quantity or standard price breaks.

3. SUBMIT A PO

We ask that all orders submitted to our sales team include part-number, item quantity and per-item price.

4. ORDER ACKNOWLEDGED

After receipt of PO, an acknowledgement will be sent by our sales team within 48 hours to verify order info, including expected ship date.

5. PRODUCTION BEGINS

Once your PO has been acknowledged, our production team will begin working on your order.

6. ORDER COMPLETED

Once your items are completed, they will be inspected, bagged and shipped per our QMS. Certificate of compliance accompanies each order.

QUALITY IN EVERY ORDER

EACH BATCH RELEASE INCLUDES

Overlook C of C

The full manufacturing package, including production logs and raw material certs, is maintained by quality for 5 years.

Gamma Certs and Indicators

Gamma-sterilized items include certs of process and color-changing gamma indicators on all labels.

Multi-Bagged Items

All non-sterile items are double-bagged and gamma-sterilized items are triple-bagged in clean room quality bags.

Detailed Packing Slip

A detailed packing slip provides all relevant order info to be easily handled by your receiving department.

Shelf Life

Gamma-sterilized items are validated to a 30-month shelf life from the date of manufacture.

Electronic Job Records

All job records are scanned to multiple secure locations and are available for reference upon request.